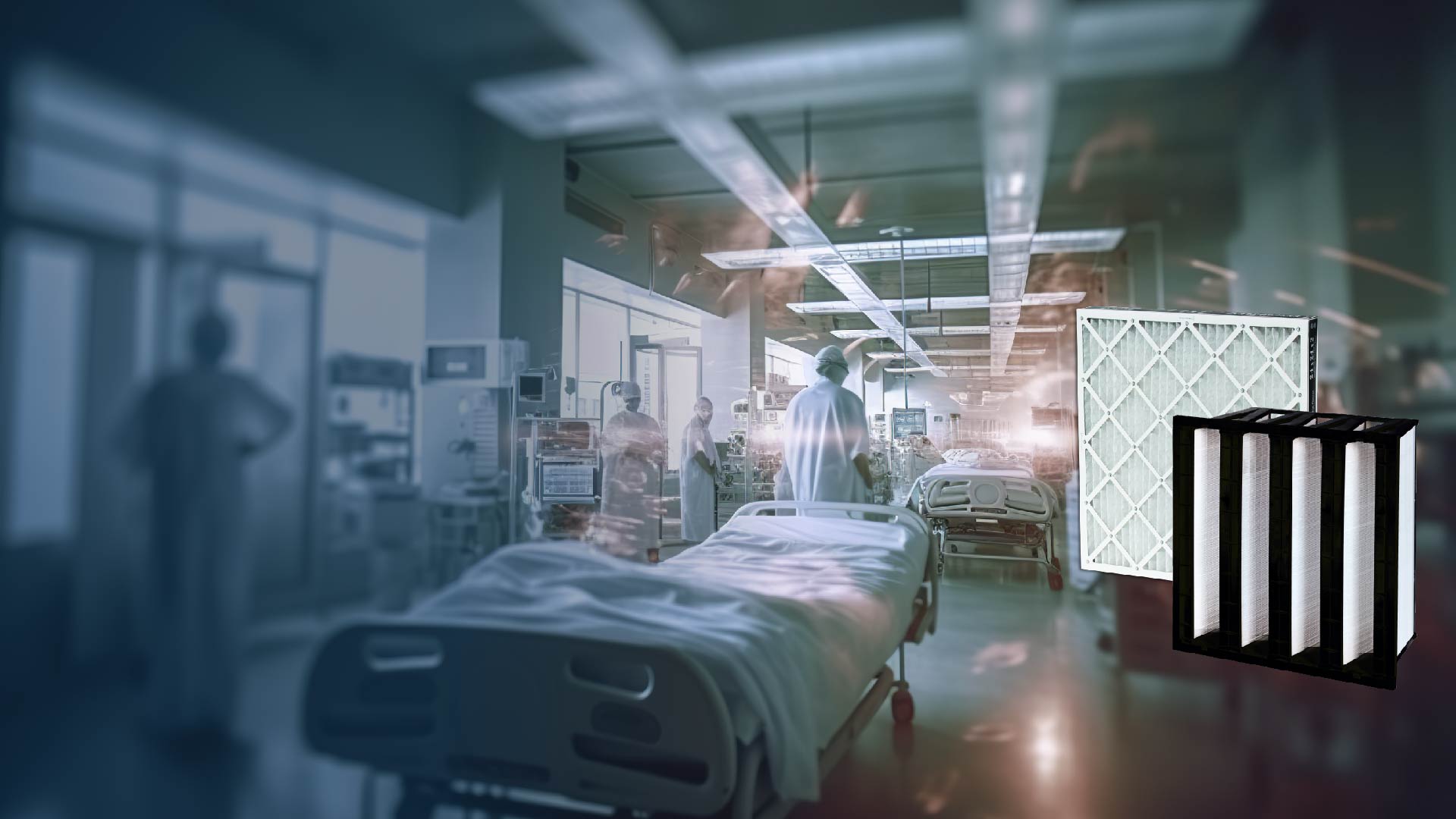

WE HELP CREATE STERILE ENVIRONMENTS IN

HEALTHCARE FACILITIES

Healthcare applications are among the highest needs for high performing air filtration. So much can be at risk – the health of patients and the health of all the doctors, nurses and other support staff.

From protecting a patient in surgery with a MERV 14 or higher filtration system and 20 air changeouts per hour to Isolation Room Containment Systems for highly infectious diseases like Ebola, Filtration Group IAQ has you covered.

Most schools systems are under constant financial burden to deliver high quality education at low cost. Sometimes cutting costs means letting HVAC maintenance lag. But, when an HVAC system isn’t properly maintained it cannot function optimally. Proper ventilation and maintenance throughout the school year is critical for student and staff health concerns. Lack of proper air filtration is one of the leading causes for illness, lack of concentration and fatigue resulting in lower grades and a higher amount of missed days.

Adding increased levels of fresh air and cleaning recirculated air not only benefits children, but provides a safer, healthier, and more productive indoor environment for teachers and staff.

With the pressures of running a business today, it is very easy to overlook the effects of Indoor Air Quality (IAQ) on financial performance. Poor IAQ has been linked by many studies to reduced worker productivity and increased absenteeism due to sickness. The consequences in retail environments are even greater – poor IAQ can cause customers to leave early or even stay away altogether. Investing in better air purification filters improves indoor air quality and increases energy efficiency.

Don’t sacrifice your human capital or prevent revenue to save on air filters. Filtration Group IAQ provides a wide range of options for light commercial strip malls to commercial high-rise buildings alike.

Infection control was likely not considered a priority when the HVAC systems in most industrial workplaces were specified. However, when properly configured with the correct amount of outdoor air, leveraging make-up air HVAC systems can lead to significant reductions in the spread of airborne pathogens.

Selecting a filter based on performance can save significantly in the long run. Avoid being shortsighted – look at the TCO and not just the purchase price of a filter and how long it can last.

Critical environments such as laboratories, or pharmaceutical and microelectronic manufacturing are very different, but they have one thing in common – contamination can lead to disastrous effects. Is your filtration system running with optimal efficiency?

Whether protecting the health of workers and the patients that will use the medicine being produced or protecting the yield of production – cleanroom filters just must work. All of FG IAQ’s HEPA and ULPA cleanroom filters are tested to make sure the claimed performance is met, because they have to.

Protecting airport staff and travelers from poor indoor air quality are extremely important given the array of emissions the public encounters while on route to new destinations. Is your ventilation environment optimized for both cost and purification?

There has been a 7% increase in airport passengers over the last year and increasing health and safety regulations. Maintaining healthy air in highly populated transportation hubs, both protects passengers and staff from harmful chemicals, bio-particulates and emissions.

Local, state and federal facilities need to implement new measures to limit the amount of time that public spend in place while practicing social distancing. However, even with these new standards, it can still be difficult to keep common area germ-free.

Government buildings need to go beyond to ensure the safety of their employees and general public in a healthy environment with indoor air hygiene that control airborne infectious disease.

CASE STUDIES

We are committed to providing the highest efficiency, highest performing, quality air filtration products and solutions serving a broad range of industries across North America.

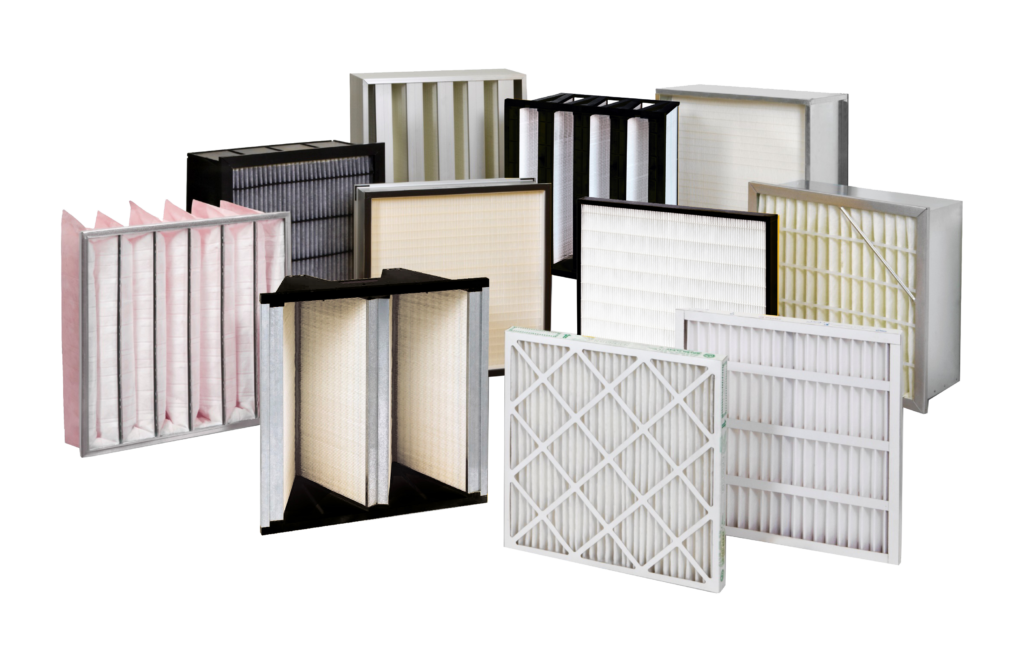

PRODUCT CATEGORIES

We produce filtration solutions to fit into HVAC systems of all kinds to ensure that you are offering healthy air to your building occupants.